Slide

new arrivals

US Orders Ship Fast

Fast and reliable shipping within the United States.

Returns

Easy returns within 30 days of delivery.

Payments

100% secure payment processing.

Support online

Support online, always here to assist you with care.

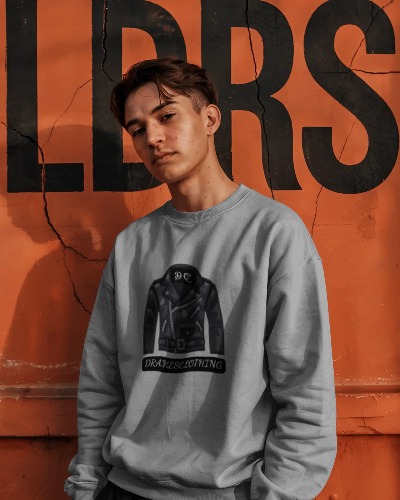

bestseller

Shop by Category

Find what you love – faster. Browse our collections by style, need or vibe.

T-shirts

Hoodies

Jackets

Sweatshirts